About our R&D

A considerable amount of effort goes into the research and development of our race derived products. Megan Racing takes great measures during R&D, pre-production, production, and post production to ensure that each individual product we produce is of the highest quality in the industry. Everything is produced under very strict quality control at overseas factories. Our factory and production methods are ISO9001 (International Standard Organization) certified since the beginning of the millennium taking the standards of automotive performance to new heights.

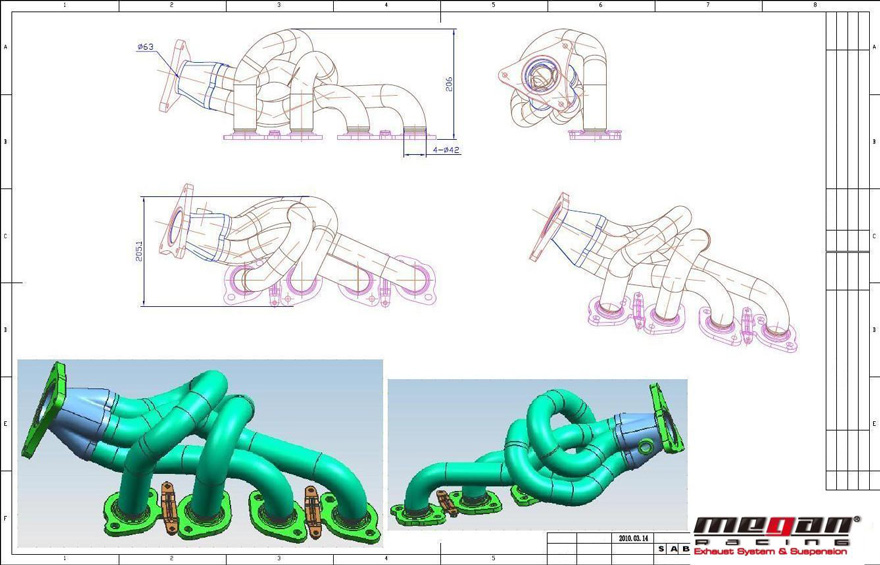

By never compromising on quality, performance potential is unlimited. In the development process of a new product, once we decide on a product for a particular application, we use CAD design to build a computerized representation of the product which allows us to conduct stress analysis based on materials used. Once a prototype has been produced, we continue to the next phase of R&D where we test for fitment and assure it handles the stresses seen in a daily driven vehicle.

Once the prototype passes this phase of testing, we proceed to test the items on the race track, whether it be for drift days or open test track days, we test the products to prove they perform and that they perform well and beyond expectations. Whether it is maximum attainable slip angles, or improvements in lap times, data collection is just part of the extensive R&D process. One thing everyone must know about our R&D process is that the R&D never reaches a “final stage.” Products can always be improved upon, whether it be the utilization of new, stronger, and lighter materials or improvements in design.